7.3 - 7.5 G/Cm3 Density Alnico Magnet For Long Lasting Generators Excellent Performance

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Tolerance | ±0.05mm | Maximum Working Temperature | 450-550°C |

|---|---|---|---|

| Manufacturing Process | Casting Or Sintering | Applications | Sensors, Motors, Generators, Loudspeakers, Magnetic Separators, Etc. |

| Composite | AlNiCo Magnet | Shape | Bar, Disc, Ring, Block, Cylinder |

| Max Working Temperature | 550Degree C | Material | Alnico |

| Highlight | 7.3G/cm3 magnet alnico,7.5G/cm3 magnet alnico,Long Lasting flexible rare earth magnets |

||

7.3-7.5 G/cm3 Density Alnico Magnet for Long-lasting Generators excellent performance

Product Description:

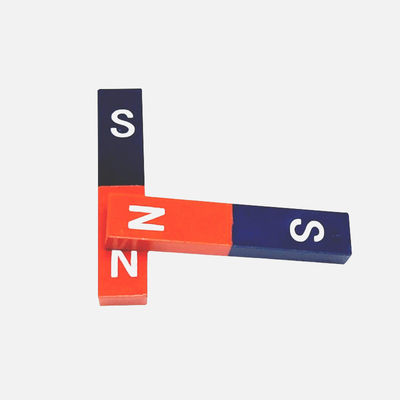

Alnico Magnet, also known as Aluminum Nickel Cobalt Magnet, is a type of permanent magnet made from an alloy of aluminum, nickel, and cobalt. It is widely used in various industrial and commercial applications due to its exceptional magnetic properties and high temperature resistance.

Alnico Magnet is composed of aluminum, nickel, cobalt, and iron, along with other elements such as copper and titanium. These materials are melted together and then cast into different shapes, such as blocks, discs, cylinders, and rings, depending on the application requirements.

One of the key features of Alnico Magnet is its high temperature resistance. With a maximum working temperature range of 450-550°C, it is able to maintain its strong magnetic properties even in extreme heat. This makes it suitable for use in industrial settings where high temperatures are present, such as in motors, generators, and sensors.

Another important attribute of Alnico Magnet is its excellent stability. Unlike other types of magnets, Alnico does not easily demagnetize, making it a reliable and long-lasting option for various applications. It also has a high coercive force, which means it requires a significant amount of energy to demagnetize it.

Alnico Magnet is available in different grades, including Alnico 2, Alnico 5, and Alnico 8. Each grade has its own unique magnetic properties, allowing users to choose the most suitable one for their specific needs. Alnico 2 is known for its low coercive force and high magnetic saturation, while Alnico 5 is commonly used in guitar pickups due to its strong magnetic field. Alnico 8, on the other hand, has the highest magnetic energy of all Alnico grades.

With a density of 7.3-7.5 G/cm3, Alnico Magnet is a relatively lightweight option compared to other permanent magnets. This makes it ideal for applications where weight is a critical factor, such as in aerospace and automotive industries.

Another important specification of Alnico Magnet is its tolerance, which is ±0.05mm. This means that the actual dimensions of the magnet will not deviate more than 0.05mm from the specified dimensions, ensuring precise and accurate performance in various applications.

In conclusion, Alnico Magnet is a versatile and high-quality permanent magnet that offers exceptional stability, high temperature resistance, and strong magnetic properties. It is widely used in a variety of industrial and commercial applications, making it an essential component in many modern technologies.

Features:

- Product Name: Alnico Magnet

- Material: Alnico

- Composite: AlNiCo Magnet

- Max Working Temperature: 550Degree C

- Tolerance: ±0.05mm

- Magnetic Properties:

- High Coercivity

- High Remanence

- High Energy Product

- Durable Alnico Magnetic Material

- Industrial Alnico Magnets

- Strong Alnico Magnets

Technical Parameters:

| Composite | AlNiCo Magnet |

|---|---|

| Applications | Sensors, Motors, Generators, Loudspeakers, Magnetic Separators, Etc. |

| Tolerance | ±0.05mm |

| Manufacturing Process | Casting Or Sintering |

| Maximum Working Temperature | 450-550°C |

| Material | Alnico |

| Max Working Temperature | 550 Degrees C |

| Grade | Alnico 2, Alnico 5, Alnico 8 |

| Density | 7.3-7.5 G/cm3 |

| Magnetic Properties | High Coercivity, High Remanence, High Energy Product |

Composite: Aluminum Nickel Cobalt Magnets

Applications: Cost-effective Alnico Magnets for Sensors, Motors, Generators, Loudspeakers, Magnetic Separators, and other industrial and consumer applications.

Tolerance: ±0.05mm

Manufacturing Process: Casting or Sintering

Maximum Working Temperature: 450-550°C

Material: Alnico

Max Working Temperature: 550 Degrees C

Grade: Alnico 2, Alnico 5, Alnico 8

Density: 7.3-7.5 G/cm3

Magnetic Properties: High Coercivity, High Remanence, High Energy Product

Other Features: Suitable for high temperature applications and strong magnetic fields

Advantages: Durable, corrosion-resistant, and retains its magnetic properties even at high temperatures

Key Uses: High temperature sensors, motors, generators, loudspeakers, and magnetic separators

| Grade | MMPA | Residual Induction | Coercive Force | Max. Energy Product | Max. Working Temperature |

||

| Br | Hcb | (BH)max | Tw | ||||

| kGs | T | kOe | KA/M | MGOe KJ/m³ | ℃ | ||

| LNl0 | ALNICO3 | 6.0 | 0.60 | 0.50 | 40 | 1.25 10 | 550 |

| LNG 10 | 6.0 | 0.60 | 0.55 | 44 | 1.25 10 | 550 | |

| LNG12 | ALNICO2 | 7.0 | 0.70 | 0.55 | 44 | 1.50 12 | 550 |

| LNG 13 | 6.8 | 0.68 | 0.60 | 48 | 1.63 13 | 550 | |

| LNG16 | ALNICO4 | 8.0 | 0.80 | 0.60 | 48 | 2.00 16 | 550 |

| LNG18 | 9.0 | 0.90 | 0.60 | 48 | 2.25 18 | 550 | |

| LNG37 | ALNICOS | 12.0 | 1.20 | 0.60 | 48 | 4.63 37 | 550 |

| LNG40 | 12.3 | 1.23 | 0.60 | 48 | 5.00 40 | 550 | |

| LNG44 | 12.5 | 1.25 | 0.65 | 52 | 5.50 44 | 550 | |

| LNG48 | ALNICOSDG | 12.8 | 1.28 | 0.70 | 56 | 6.00 48 | 550 |

| LNG52 | 13.0 | 1.30 | 0.70 | 56 | 6.50 52 | 550 | |

| LNG56 | ALNICO5—7 | 13.0 | 1.30 | 0.72 | 58 | 7.00 56 | 550 |

| LNG60 | 13.3 | 1.33 | 0.75 | 60 | 7.50 60 | 550 | |

| LNGT28 | ALNICO6 | 10.0 | 1.00 | 0.70 | 56 | 3.50 28 | 550 |

| LNGT30 | 11.0 | 1.10 | 0.70 | 56 | 3.75 30 | 550 | |

| LNGT18 | ALNICO8 | 5.8 | 0.58 | 1.00 | 80 | 2.25 18 | 550 |

| LNGT32 | 8.0 | 0.80 | 1.zs | 100 | 4.00 32 | 550 | |

| LNGT38 | 8.0 | 0.80 | 1.38 | 110 | 4.75 38 | 550 | |

| LNGT44 | 8.5 | 0.85 | 1.45 | lls | 5.50 44 | 550 | |

| LNGT48 | ALNICO8HE | 9.0 | 0.90 | 1.50 | 120 | 6.00 48 | 550 |

| LNGT60 | ALNICO9 | 9.0 | 0.90 | 1.38 | 110 | 7.50 60 | 550 |

| LNGT72 | 10.5 | 1.05 | 1.40 | 112 | 9.00 72 | 550 | |

| LNGT80 | 10.8 | 1.08 | 1.50 | 120 | 10.00 80 | 550 | |

| LNGT88 | 11.0 | 1.10 | 1.45 | 115 | 11.00 88 | 550 | |

| LNGT96 | 11.5 | 1.15 | 1.48 | 118 | 12.00 96 | 550 | |

| LNGT36J | ALNICO8HC | 7.0 | 0.70 | 1.75 | 140 | 4.50 36 | 550 |

| LNGT40J | 7.0 | 0.70 | 1.75 | 140 | 5.00 40 | 550 | |

| LNGT44J | 7.5 | 0.75 | 1.75 | 140 | 5.50 44 | 550 | |

| LNGT48J | 8.0 | 0.80 | 1.82 | 145 | 6.00 48 | 550 | |

| LNGT52J | 8.5 | 0.85 | 1.75 | 140 | 6.50 52 | 550 | |

| Grade | MMPA | Residual Induction | Coercive Force | Max. Energy Product | Max. Working Temperature |

||

| Br | Hcb | (BH)max | Tw | ||||

| kGs | T | kOe | KA/M | MGOe KJ/m³ | ℃ | ||

| FLN8 | S.ALNICO3 | 5.0 | 0.50 | 0.50 | 40 | 1.00 8 | 450 |

| FLNG12 | S.ALNICO2 | 6.5 | 0.65 | 0.60 | 48 | 1.50 12 | 450 |

| FLNGT18 | S.ALNICO7 | 6.0 | 0.60 | 1.13 | 90 | 2.20 18 | 450 |

| FLNG34 | S.ALNICO5 | 12.0 | 1.20 | 0.60 | 48 | 4.25 34 | 450 |

| FLNGT28 | S.ALNICO6 | 10.5 | 1.05 | 0.70 | 56 | 3.50 28 | 450 |

| FLNGT38 | S.ALNICO8 | 8.0 | 0.80 | 1.50 | 120 | 4.75 38 | 450 |

| FLNGT42 | S.ALNICO8 | 8.8 | 0.88 | 1.50 | 120 | 5.25 42 | 450 |

| FLNGT33J | S.ALNICO8HC | 7.0 | 0.70 | 1.75 | 140 | 4.13 33 | 450 |

Applications:

The Alnico Magnet, also known as the AlNiCo Magnet, is a type of permanent magnet made of an alloy of aluminum, nickel, and cobalt. Alnico magnets are known for their strong magnetic properties and high-temperature resistance, making them suitable for a wide range of industrial applications. JN, a leading manufacturer of magnetic products, offers a variety of Alnico magnets under the brand name JN-AL-3. These magnets are produced in China and meet international standards, including ISO9001 certification.

| Brand Name | Model Number | Place of Origin | Certification | Minimum Order Quantity | Price | Packaging Details | Delivery Time | Payment Terms | Supply Ability | Composite | Density | Material |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| JN | JN-AL-3 | China | ISO9001 | 1000PCS | Negotiable | By Sea Pallet /By Air Carton / By Express Packaging | 25 Days | L/C, T/T | 2000K PCS/Month | AlNiCo Magnet | 7.3-7.5 G/cm3 | Alnico |

Alnico magnets have a wide range of industrial applications, including:

- Sensors: Alnico magnets are commonly used in sensors for measuring temperature, pressure, and magnetic fields. Their stable magnetic properties and high-temperature resistance make them ideal for this purpose.

- Generators: Alnico magnets are often used in generators to convert mechanical energy into electrical energy. They are known for their strong magnetic fields, making them suitable for generating large amounts of power.

- Motors: Alnico magnets are commonly used in motors for various applications, such as electric cars, power tools, and industrial machinery. Their high-temperature resistance and strong magnetic properties make them ideal for producing efficient and reliable motors.

- Loudspeakers: Alnico magnets are widely used in the production of high-quality loudspeakers. Their strong magnetic fields and stable properties allow for clear and accurate sound reproduction.

- Magnetic Separators: Alnico magnets are commonly used in magnetic separators to remove unwanted magnetic materials from products in industries such as mining, recycling, and pharmaceuticals.

With its high-temperature resistance and strong magnetic properties, the Alnico magnet is also suitable for applications in extreme environments, such as aerospace and defense.

Alnico magnets can be produced using two methods: casting or sintering. In the casting process, the molten alloy is poured into a mold and then cooled to form the desired shape. In the sintering process, the alloy is heated and pressed into a mold to form the desired shape. Both processes result in high-quality Alnico magnets with excellent magnetic properties.

JN's Alnico magnets, with its brand name JN-AL-3, are a reliable and high-quality choice for various industrial applications. Made in China with ISO9001 certification, our Alnico magnets offer strong magnetic properties, high-temperature resistance, and custom options to meet your specific needs. With a minimum order quantity of 1000PCS and a supply ability of 2000K PCS/month, JN is ready to meet your demand for Alnico magnets. Contact us today to learn more or to request a quote.

Customization:

Looking for powerful Alnico magnets to meet your specific needs? JN offers customized Alnico magnets in various sizes and shapes for a wide range of applications. Our Alnico magnets are made from magnetic alloys of aluminum-nickel-cobalt, known for their high temperature stability and reliable performance.

- Brand Name: JN

- Model Number: JN-AL-3

- Place of Origin: China

- Certification: ISO9001

- Minimum Order Quantity: 1000PCS

- Price: Negotiable

- Packaging Details: By Sea Pallet / By Air Carton / By Express Packaging

- Delivery Time: 25 Days

- Payment Terms: L/C, T/T

- Supply Ability: 2000K PCS/Month

- Composite: AlNiCo Magnet

- Density: 7.3-7.5 g/cm3

- Manufacturing Process: Casting or Sintering

- Tolerance: ±0.05mm

- Grade: Alnico 2, Alnico 5, Alnico 8

JN Alnico magnets can be customized according to your specific requirements. We offer:

- Customized sizes and shapes

- Precision tolerance of ±0.05mm

- Various grades to choose from: Alnico 2, Alnico 5, Alnico 8

Our Alnico magnets are manufactured under strict quality control processes and are ISO9001 certified, ensuring consistent and reliable performance.

JN Alnico magnets are widely used in various industries such as:

- Automotive

- Electronics

- Motors and generators

- Medical equipment

- Musical instruments

- And more

Experience the power and versatility of JN Alnico magnets. Contact us today for your customized magnet solution.

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is JN.

- Q: What is the model number of this product?

- A: The model number of this product is JN-AL-3.

- Q: Where is this product manufactured?

- A: This product is manufactured in China.

- Q: Does this product have any certifications?

- A: Yes, this product is certified with ISO9001.

- Q: What is the minimum order quantity for this product?

- A: The minimum order quantity for this product is 1000PCS.

- Q: Is the price of this product negotiable?

- A: Yes, the price of this product is negotiable.

- Q: How is this product packaged for shipment?

- A: This product can be packaged for shipment by sea pallet, air carton, or express packaging.

- Q: What is the average delivery time for this product?

- A: The average delivery time for this product is 25 days.

- Q: What are the accepted payment terms for this product?

- A: The accepted payment terms for this product are L/C and T/T.

- Q: What is the supply ability of this product?

- A: The supply ability for this product is 2000K PCS per month.