Isotropic And Anisotropic SmCo Magnet Cylinder Long-Lasting Corrosion Resistance

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mechanical Properties | Brittle, Hard, Difficult To Machine | Tolerance | 0.1mm |

|---|---|---|---|

| Magnetic Properties | High Magnetic Energy Product, High Coercive Force, High Remanence | Shape | Disc, Cylinder, Block, Ring, Arc, Segment, Etc. |

| Color | Brown, Black | Magnetization | Multipolar Or So |

| Property | Isotropic And Anisotropic Is Avaible | Advantages | High Temperature Stability, High Magnetic Strength, Corrosion Resistance |

| Highlight | OEM samarium cobalt permanent magnets,Anisotropic samarium cobalt permanent magnets,Magnetic Separators rectangular rare earth magnets |

||

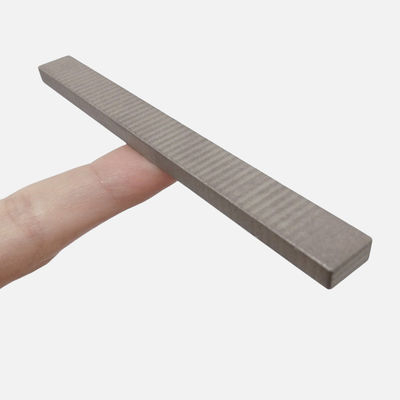

Isotropic And Anisotropic SmCo Magnet Cylinder Long-Lasting Corrosion Resistance

Product Description:

The Permanent Magnet SmCo, also known as Cobalt SmCo Magnet, is a type of rare earth magnet that is made from an alloy of samarium and cobalt. It is known for its high magnetic strength and excellent temperature stability, making it a popular choice for various industrial applications. The SmCo Magnet comes in different shapes and sizes, with the most common ones being disc and ring magnets.

Mechanical Properties:

- Brittle: The SmCo Magnet is a brittle material, which means it is prone to cracking or breaking under stress.

- Hard: With a high Vickers hardness, the SmCo Magnet is a tough and durable material that can withstand harsh environmental conditions.

- Difficult To Machine: Due to its hardness and brittleness, the SmCo Magnet is challenging to machine, making it a more expensive option compared to other magnets.

Demagnetization Resistance: The SmCo Magnet has excellent demagnetization resistance, meaning it can retain its magnetic properties even under extreme heat or strong external magnetic fields.

Tolerance: The SmCo Magnet has a high precision level, with a tolerance of 0.1mm. This makes it suitable for applications that require precise positioning and alignment.

Property: The SmCo Magnet is available in both isotropic and anisotropic forms. Isotropic magnets have the same magnetic properties in all directions, while anisotropic magnets have a preferred direction of magnetization.

Advantages:

- High Temperature Stability: The SmCo Magnet can maintain its magnetic strength even at high temperatures, up to 350°C.

- High Magnetic Strength: The SmCo Magnet has a high magnetic energy product, making it one of the strongest permanent magnets available.

- Corrosion Resistance: The SmCo Magnet is resistant to corrosion, making it suitable for use in harsh environments or applications that involve exposure to moisture or chemicals.

Features:

- Product Name: SmCo Magnet

- Applications: Motors, Sensors, Magnetic Couplings, Magnetic Separators, Etc.

- Color: Brown, Black

- Curie Temperature: 700-800°C

- Magnetic Properties:

- High Magnetic Energy Product

- High Coercive Force

- High Remanence

- Advantages:

- High Temperature Stability

- High Magnetic Strength

- Corrosion Resistance

Key Features:

- Samarium Cobalt Magnet

- Ring SmCo Magnet

- Samarium Cobalt Magnet Block

Technical Parameters:

| Product Name | Ring SmCo Magnet |

|---|---|

| Material | SmCo Rare Earth Magnet, Samarium Cobalt Magnet |

| Magnetization | Multipolar Or So |

| Shape | Disc, Cylinder, Block, Ring, Arc, Segment, Etc. |

| Color | Brown, Black |

| Tolerance | 0.1mm |

| Demagnetization Resistance | Excellent |

| Property | Isotropic And Anisotropic Is Avaible |

| Magnetic Properties | High Magnetic Energy Product, High Coercive Force, High Remanence |

| Applications | Motors, Sensors, Magnetic Couplings, Magnetic Separators, Etc. |

| Mechanical Properties | Brittle, Hard, Difficult To Machine |

| Curie Temperature | 700-800°C |

| Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force |

Max. Energy Product |

Max. Working Temperature | ||||||

| Br | Hcb | Hcj | (BH)max | Tw | |||||||

| kGs | T | kOe | KA/m | kOe | KA/m | MGOe | KJ/m³ | ℃ | |||

| SmCo5 | SC16 | 8.1-8.5 | 0.81-0.85 | 7.8-8.3 | 620-660 | 15-23 | 1194-1830 | 14-16 | 110-127 | 250 | |

| SC18 | 8.5-9.0 | 0.85-0.90 | 8.3-8.8 | 660-700 | 15-23 | 1194-1830 | 16-18 | 127-143 | 250 | ||

| SC20 | 9.0-9.4 | 0.90-0.94 | 8.5-9.1 | 676-725 | 15-23 | 1194-1830 | 19-21 | 150-167 | 250 | ||

| SC22 | 9.2-9.6 | 0.92-0.96 | 8.9-9.4 | 710-748 | 15-23 | 1194-1830 | 20-22 | 160-175 | 250 | ||

| SC24 | 9.6-10.0 | 0.96- 1.00 | 9.2-9.7 | 730-770 | 15-23 | 1194-1830 | 22-24 | 175-190 | 250 | ||

| Sm2Co17 | SCS22 | 9.3-9.7 | 0.93-0.97 | 8.5-9.3 | 676-740 | >18 | >1433 | 20-23 | 160-183 | 350 | |

| SCS24 | 9.5-10.2 | 0.95- 1.02 | 8.7-9.6 | 692-764 | >18 | >1433 | 22-24 | 175-191 | 350 | ||

| SCS24H | 9.5-10.2 | 0.95- 1.02 | 8.7-9.6 | 692-764 | >25 | >1990 | 22-24 | 175-191 | 350 | ||

| SCS26M | 10.2-10.5 | 1.02- 1.05 | 8.5-9.8 | 676-780 | 12-18 | 955-1433 | 24-26 | 191-207 | 350 | ||

| SCS26 | 10.2-10.5 | 1.02- 1.05 | 9.4-10.0 | 748-796 | >18 | >1433 | 24-26 | 191-207 | 350 | ||

| SCS26H | 10.2-10.5 | 1.02- 1.05 | 9.4-10.0 | 748-796 | >25 | >1990 | 24-26 | 191-207 | 350 | ||

| SCS28M | 10.3-10.8 | 1.03- 1.08 | 8.5-10.0 | 676-796 | 12-18 | 955-1433 | 26-28 | 207-223 | 350 | ||

| SCS28 | 10.3-10.8 | 1.03- 1.08 | 9.5-10.2 | 796-812 | >18 | >1433 | 26-28 | 207-223 | 350 | ||

| SCS28H | 10.3-10.8 | 1.03- 1.08 | 9.5-10.2 | 796-812 | >25 | >1990 | 26-28 | 207-223 | 350 | ||

| SCS30M | 10.8-11.0 | 1.08- 1.10 | 8.5-10.5 | 676-835 | 12-18 | 955-1433 | 28-30 | 223-239 | 350 | ||

| SCS30 | 10.8-11.0 | 1.08- 1.10 | 9.9-10.5 | 788-835 | >18 | >1433 | 28-30 | 223-239 | 350 | ||

| SCS30H | 10.8-11.0 | 1.08- 1.10 | 9.9-10.5 | 788-835 | >25 | >1990 | 28-30 | 223-239 | 350 | ||

| SCS32M | 11.0-11.3 | 1.10-1.13 | 8.5-10.7 | 676-852 | 12-18 | 955-1433 | 29-32 | 231-255 | 350 | ||

| SCS32 | 11.0-11.3 | 1.10-1.13 | 10.2-10.8 | 812-860 | >18 | >1433 | 29-32 | 231-255 | 350 | ||

| SCS32H | 11.0-11.3 | 1.10-1.13 | 10.2-10.8 | 812-860 | >25 | >1990 | 29-32 | 231-255 | 350 | ||

| SCS35 | 11.6-12.0 | 1.16-1.20 | 10.9-11.4 | 868-908 | >18 | >1433 | 32-35 | 255-278 | 350 | ||

| Low Temp Coeff Sm2Co17 | SCL18LT | 8.4-8.9 | 0.84-0.89 | 7.9-8.4 | 629-668 | >18 | >1433 | 17-19 | 135-151 | 350 | |

| SCL20LT | 8.9-9.4 | 0.89-0.94 | 8.3-8.9 | 660-708 | >18 | >1433 | 19-21 | 151-167 | 350 | ||

| SCL22LT | 9.4-9.8 | 0.94-0.98 | 8.7-9.3 | 692-740 | >18 | >1433 | 21-23 | 167-183 | 350 | ||

| High Temp Resistance Sm2Co17 | SCG24 | 9.9-10.4 | 0.99- 1.04 | 9.3-9.9 | 740-788 | >23 | >1830 | 23-25 | 183-199 | 400 | |

| SCG22 | 9.4-9.9 | 0.94-0.99 | 8.8-9.4 | 700-748 | >23 | >1830 | 21-23 | 167-183 | 450 | ||

| SCG20 | 8.9-9.4 | 0.89-0.94 | 8.3-8.9 | 660-708 | >23 | >1830 | 19-21 | 151-167 | 500 | ||

Applications:

Brand Name: JN

Model Number: JN-CO-2

Place of Origin: CHINA

Certification: ISO9001

Minimum Order Quantity: 500PCS

Price: Negotiable

Packaging Details: By Sea Pallet /By Air Carton / By Express Packaging

Delivery Time: 25 Days

Payment Terms: L/C,T/T

Supply Ability: 500K PCS/Month

Tolerance: 0.1mm

Demagnetization Resistance: Excellent

Advantages: High Temperature Stability, High Magnetic Strength, Corrosion Resistance

Shape: Disc, Cylinder, Block, Ring, Arc, Segment, Etc.

Mechanical Properties: Brittle, Hard, Difficult To Machine

SmCo magnets are made from a combination of samarium, cobalt, and other rare earth elements. They are known for their high temperature stability, high magnetic strength, and excellent corrosion resistance. These magnets are available in various shapes such as disc, cylinder, block, ring, arc, and segment, making them suitable for a wide range of applications.

The high temperature stability of SmCo magnets makes them ideal for use in high temperature environments, such as in motors, generators, and sensors. They are also commonly used in medical equipment, aerospace technology, and military equipment. Their high magnetic strength makes them suitable for use in magnetic couplings, magnetic separators, and magnetic bearings. SmCo magnets are also widely used in the field of renewable energy, such as in wind turbines and electric vehicles.

- High Temperature Stability: SmCo magnets can maintain their magnetic properties at temperatures up to 350°C, making them suitable for use in high temperature applications.

- High Magnetic Strength: SmCo magnets have a high magnetic strength, which allows them to generate strong magnetic fields.

- Corrosion Resistance: SmCo magnets are resistant to corrosion, making them suitable for use in harsh environments.

- Various Shapes: SmCo magnets are available in various shapes, providing flexibility in design and application.

- Excellent Demagnetization Resistance: SmCo magnets have excellent demagnetization resistance, ensuring long-term stability and reliability.

JN offers a wide range of SmCo magnets, including:

- Bar SmCo Magnet: These magnets are available in different lengths and diameters, and are commonly used in motors, sensors, and loudspeakers.

- Ring SmCo Magnet: These magnets are used in applications where a circular magnetic field is required, such as in generators and magnetic couplings.

- Block SmCo Magnet: These magnets have a rectangular shape and are commonly used in sensors, switches, and magnetic separators.

JN's SmCo magnets are known for their high temperature stability, high magnetic strength, and excellent corrosion resistance. With a wide range of shapes and sizes available, they are suitable for various applications in industries such as automotive, aerospace, and renewable energy. Contact us today to learn more about our SmCo magnets and how they can benefit your business.

Customization:

Brand Name: JN

Model Number: JN-CO-2

Place of Origin: CHINA

Certification: ISO9001

Minimum Order Quantity: 500PCS

Price: Negotiable

Packaging Details: By Sea Pallet /By Air Carton / By Express Packaging

Delivery Time: 25 Days

Payment Terms: L/C,T/T

Supply Ability: 500K PCS/Month

- Bar SmCo Magnet : Available in various sizes and shapes, including rectangular and cylindrical, to meet different application needs.

- High Temperature SmCo Magnet : Can withstand temperatures up to 700-800°C, making it suitable for use in high temperature environments.

- Block SmCo Magnet : Can be customized into blocks of different dimensions to provide stronger magnetic force and stability.

- Ring SmCo Magnet : Can be made into rings of different sizes and thicknesses, ideal for use in motors and generators.

- Segment SmCo Magnet : Can be segmented into smaller pieces for precision applications and to create multi-pole magnets.

- High Magnetic Energy Product : Provides strong magnetic force for efficient performance.

- High Coercive Force : Resists demagnetization and maintains its magnetic strength over time.

- High Remanence : Retains its magnetization even after the external magnetic field is removed.

- High Temperature Stability : Can maintain its magnetic properties even in extreme temperature conditions.

- High Magnetic Strength : Offers stronger magnetic force compared to other types of magnets.

- Corrosion Resistance : Can withstand harsh environments and resist corrosion for longer lifespan.

Our SmCo magnets can be magnetized in multipolar or so configurations to meet different application requirements.

Packing and Shipping:

The SmCo magnet, also known as samarium-cobalt magnet, is a type of rare earth magnet that is known for its high magnetic strength and resistance to corrosion and demagnetization. Due to its unique properties, proper packaging and handling during shipping is crucial to ensure its quality and performance.

SmCo magnets are typically packaged in a protective material such as foam or plastic to prevent any damage during transportation. The magnets are also usually coated with a protective layer, such as nickel or epoxy, to prevent corrosion and maintain their magnetic strength.

In addition, the packaging should be designed to avoid any direct contact between the magnets, as they can easily demagnetize or break if they collide with each other. This can be achieved by using individual compartments or layers within the packaging.

It is also recommended to label the packaging with the type and grade of the SmCo magnet, as well as any handling instructions or warning labels.

When shipping SmCo magnets, it is important to choose a reliable and experienced shipping provider to ensure the safe and timely delivery of the magnets. The magnets should be securely packed in a sturdy box with appropriate cushioning materials to prevent any movement during transit.

Depending on the quantity and size of the magnets, they may need to be shipped as hazardous materials due to their strong magnetic field. In such cases, it is necessary to comply with all shipping regulations and provide the necessary documentation.

It is also recommended to use a tracking service to monitor the shipment and ensure its safe arrival. In case of any damage or loss during shipping, it is important to contact the shipping provider and the manufacturer for assistance.

Proper packaging and shipping of SmCo magnets is essential in maintaining their quality and performance. By following these guidelines, customers can receive their magnets in excellent condition, ready to be used for various applications.

FAQ:

- Q: What is the brand name of this product?

A: The brand name is JN. - Q: What is the model number of this product?

A: The model number is JN-CO-2. - Q: Where is this product made?

A: This product is made in China. - Q: Is this product certified?

A: Yes, this product is certified with ISO9001. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity is 500PCS. - Q: Is the price negotiable for this product?

A: Yes, the price is negotiable. - Q: How is this product packaged?

A: This product can be packaged by sea pallet, air carton, or express packaging. - Q: What is the estimated delivery time for this product?

A: The estimated delivery time is 25 days. - Q: What are the accepted payment terms for this product?

A: The accepted payment terms are L/C and T/T. - Q: What is the supply ability for this product?

A: The supply ability is 500K PCS per month.