Vacuum Cleaner NdFeB Magnet Speed Motor Sintering Process Can Withstand Centrifugal Forces Of Up To 130,000 RPM

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Coating | Nickel Zn Ni-cu-ni | Type Of Magnet | NdFeB Magnets |

|---|---|---|---|

| Process | Sintering | Size | Custom |

| Tolerance | +/- 0.02 Mm | Raw Material | NdFeB Rare Earth Materials |

| Application | High-speed Motor Sewing Machine High-speed Hair Dryer High-efficiency Vacuum Cleaner | Compressive Strength | 1,000 N |

| Category | Neodymium Magnets | ||

| Highlight | Sintering Process NdFeB Magnet,130,000 RPM NdFeB Magnet,Vacuum Cleaner NdFeB Magnet |

||

Vacuum Cleaner NdFeB Magnet speed Motor Sintering Process can withstand centrifugal forces of up to 130,000 RPM

Product Description:

One of the key advantages of the NdFeB magnet is its strength. Made from NdFeB rare earth materials, this type of magnet is capable of generating high magnetic fields with relatively small volumes. This makes it an ideal choice for applications where space is at a premium, or where a strong magnetic field is required in a small area.

The NdFeB magnet is created through a process known as sintering. This involves heating the raw material to a high temperature, and then cooling it quickly to form a solid material. This process helps to create a very pure and homogeneous magnet that is highly resistant to corrosion and other forms of degradation.

The NdFeB magnet is available in a range of grades, including N35-N55, 42M-54M, 40H-54H, 30SH-52SH, 28UH-48UH, 28EH-38EH, and 28AH-40AH. These grades refer to the strength and performance characteristics of the magnet, with higher grades generally being more powerful and more expensive.

The NdFeB magnet is a highly versatile and reliable type of magnet that offers a range of benefits in a variety of applications. The strong magnets can withstand centrifugal forces of up to 130,000 RPM and pressures of up to 1,000 N.Whether you need a strong and durable magnet for a high-speed motor or a high-efficiency vacuum cleaner, the Neodymium Iron Boron Magnet is a great choice. And with its high tensile strength, sintering process, and use of rare earth materials, this Rare Earth Magnet is sure to provide reliable performance for years to come.

Features:

- Product Name: NdFeB Magnet

- Magnetization Methods:

- Axial Single-Pole

- Radial Multipolar

- Radial Radiate Ring

- Coating: Nickel Zn Ni-cu-ni

- Tolerance: +/- 0.02 Mm

- Size: Custom

- Raw Material: NdFeB Rare Earth Materials

Type:Neodymium Permanent Magnet, Super Strong Magnet

Applications:

These magnets are perfect for a variety of high-speed applications such as motors, sewing machines, hair dryers, and vacuum cleaners. They are known for their high efficiency and fast speed, making them a popular choice among manufacturers.

With ISO9001 certification, you can trust the quality of these magnets. The minimum order quantity is 1000pcs, and the price is negotiable depending on the quantity ordered. Packaging options include sea pallet, air carton, or express packaging, and delivery time is typically 21 days.

JN has a supply ability of 1,000k pcs/month, ensuring that you will have access to the magnets you need when you need them. Payment terms include L/C and T/T.

In summary, the JN-ND-39 NdFeB Magnet is a high-quality and reliable choice for any application that requires a super strong and rare earth magnet. Trust JN for all of your magnet needs.

| Magnetic Properties | ||||||||||

| Grade | Remanence | Intrinsic Coercivity | Max Magnetic Energy Product | Temperature Coefficient | Max Working Temperture | Density | ||||

| Br | Hcj | (BH)max | α Br | β Hcj | Tw | ρ | ||||

| T | kGs | kA/m | kOe | KJ/m3 | MGOe | %/℃ | %/℃ | ℃ | g/cm2 | |

| N55 | ≥1.45 | ≥14.5 | ≥955 | ≥12 | 406-437 | 51-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N54 | ≥1.44 | ≥14.4 | ≥955 | ≥12 | 398-437 | 50-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N52 | 1.42-1.44 | 14.2-14.4 | ≥955 | ≥12 | 390-422 | 49-53 | -0.12 | -0.8 | 80 | ≥7.5 |

| N50 | 1.4-1.42 | 14-14.2 | ≥955 | ≥12 | 374-406 | 47-51 | -0.12 | -0.8 | 80 | ≥7.5 |

| N48 | 1.37-1.4 | 13.7-14 | ≥955 | ≥12 | 366-390 | 46-49 | -0.12 | -0.8 | 80 | ≥7.5 |

| N45 | 1.32-1.37 | 13.2-13.7 | ≥955 | ≥12 | 342-366 | 43-46 | -0.12 | -0.8 | 80 | ≥7.5 |

| 54M | ≥1.44 | ≥14.4 | ≥1114 | ≥14 | 398-422 | 50-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 52M | 1.42-1.44 | 14.2-14.4 | ≥1114 | ≥14 | 390-422 | 49-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 50M | 1.4-1.42 | 14-14.2 | ≥1114 | ≥14 | 374-406 | 47-51 | -0.12 | -0.8 | 100 | ≥7.5 |

| 48M | 1.37-1.4 | 13.7-14 | ≥1114 | ≥14 | 366-390 | 46-49 | -0.12 | -0.8 | 100 | ≥7.5 |

| 45M | 1.32-1.37 | 13.2-13.7 | ≥1114 | ≥14 | 342-366 | 43-46 | -0.12 | -0.8 | 100 | ≥7.5 |

| 42M | 1.28-1.32 | 12.8-13.2 | ≥1114 | ≥14 | 318-342 | 40-43 | -0.12 | -0.8 | 100 | ≥7.5 |

| 54H | ≥1.44 | ≥14.4 | ≥1353 | ≥17 | 398-422 | 50-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52H | 1.42-1.44 | 14.2-14.4 | ≥1353 | ≥17 | 390-422 | 49-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 50H | 1.4-1.42 | 14-14.2 | ≥1353 | ≥17 | 374-406 | 47-51 | -0.12 | -0.7 | 120 | ≥7.5 |

| 48H | 1.37-1.4 | 13.7-14 | ≥1353 | ≥17 | 366-390 | 46-49 | -0.12 | -0.7 | 120 | ≥7.5 |

| 45H | 1.32-1.37 | 13.2-13.7 | ≥1353 | ≥17 | 342-366 | 43-46 | -0.12 | -0.7 | 120 | ≥7.5 |

| 42H | 1.28-1.32 | 12.8-13.2 | ≥1353 | ≥17 | 318-342 | 40-43 | -0.12 | -0.7 | 120 | ≥7.5 |

| 40H | 1.26-1.28 | 12.6-12.8 | ≥1353 | ≥17 | 302-326 | 38-41 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52SH | 1.42-1.44 | 14.2-14.4 | ≥1592 | ≥20 | 390-422 | 49-53 | -0.12 | -0.6 | 150 | ≥7.5 |

| 50SH | 1.4-1.42 | 14-14.2 | ≥1592 | ≥20 | 374-406 | 47-51 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48SH | 1.37-1.4 | 13.7-14 | ≥1592 | ≥20 | 366-390 | 46-49 | -0.12 | -0.6 | 150 | ≥7.5 |

| 45SH | 1.32-1.37 | 13.2-13.7 | ≥1592 | ≥20 | 342-366 | 43-46 | -0.12 | -0.6 | 150 | ≥7.5 |

| 42SH | 1.28-1.32 | 12.8-13.2 | ≥1592 | ≥20 | 318-342 | 40-43 | -0.12 | -0.6 | 150 | ≥7.5 |

| 40SH | 1.26-1.28 | 12.6-12.8 | ≥1592 | ≥20 | 302-326 | 38-41 | -0.12 | -0.6 | 150 | ≥7.5 |

| 38SH | 1.22-1.26 | 12.2-12.6 | ≥1592 | ≥20 | 287-310 | 36-39 | -0.12 | -0.6 | 150 | ≥7.5 |

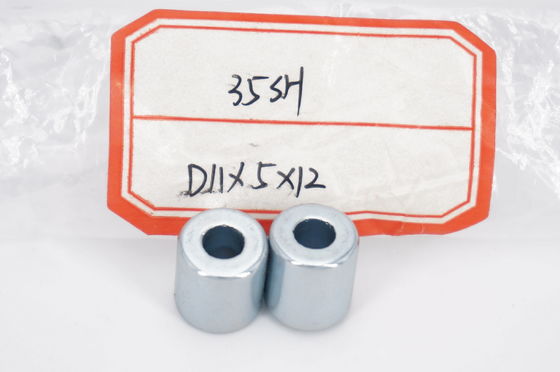

| 35SH | 1.17-1.22 | 11.7-12.2 | ≥1592 | ≥20 | 263-287 | 33-36 | -0.12 | -0.6 | 150 | ≥7.5 |

| 33SH | 1.13-1.17 | 11.3-11.7 | ≥1592 | ≥20 | 247-271 | 31-34 | -0.12 | -0.6 | 150 | ≥7.5 |

| 30SH | 1.08-1.13 | 10.8-11.3 | ≥1592 | ≥20 | 223-254 | 28-32 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48UH | 1.36-1.4 | 13.6-14 | ≥1990 | ≥25 | 366-390 | 46-49 | -0.12 | -0.6 | 180 | ≥7.5 |

| 45UH | 1.32-1.37 | 13.2-13.7 | ≥1990 | ≥25 | 342-366 | 43-46 | -0.12 | -0.6 | 180 | ≥7.5 |

| 42UH | 1.28-1.32 | 12.8-13.2 | ≥1990 | ≥25 | 318-342 | 40-43 | -0.12 | -0.6 | 180 | ≥7.5 |

| 40UH | 1.26-1.28 | 12.6-12.8 | ≥1990 | ≥25 | 302-326 | 38-41 | -0.12 | -0.6 | 180 | ≥7.5 |

| 38UH | 1.22-1.26 | 12.2-12.6 | ≥1990 | ≥25 | 287-310 | 36-39 | -0.12 | -0.6 | 180 | ≥7.5 |

| 35UH | 1.17-1.22 | 11.7-12.2 | ≥1990 | ≥25 | 263-287 | 33-36 | -0.12 | -0.6 | 180 | ≥7.5 |

| 33UH | 1.13-1.17 | 11.3-11.7 | ≥1990 | ≥25 | 247-271 | 31-34 | -0.12 | -0.6 | 180 | ≥7.5 |

| 30UH | 1.08-1.13 | 10.8-11.3 | ≥1990 | ≥25 | 223-255 | 28-32 | -0.12 | -0.51 | 180 | ≥7.5 |

| 28UH | 1.02-1.08 | 10.2-10.8 | ≥1990 | ≥25 | 207-231 | 26-29 | -0.12 | -0.51 | 180 | ≥7.5 |

| 42EH | 1.28-1.32 | 12.8-13.2 | ≥2388 | ≥30 | 318-342 | 40-43 | -0.12 | -0.5 | 200 | ≥7.5 |

| 40EH | 1.25-1.28 | 12.5-12.8 | ≥2388 | ≥30 | 302-326 | 38-41 | -0.12 | -0.5 | 200 | ≥7.5 |

| 38EH | 1.22-1.26 | 12.2-12.6 | ≥2388 | ≥30 | 287-310 | 36-39 | -0.12 | -0.5 | 200 | ≥7.5 |

| 35EH | 1.17-1.22 | 11.7-12.2 | ≥2388 | ≥30 | 263-287 | 33-36 | -0.12 | -0.5 | 200 | ≥7.5 |

| 33EH | 1.13-1.17 | 11.3-11.7 | ≥2388 | ≥30 | 247-271 | 31-34 | -0.12 | -0.5 | 200 | ≥7.5 |

| 30EH | 1.08-1.13 | 10.8-11.3 | ≥2388 | ≥30 | 223-255 | 28-32 | -0.12 | -0.51 | 200 | ≥7.5 |

| 28EH | 1.02-1.08 | 10.2-10.8 | ≥2388 | ≥30 | 207-231 | 26-29 | -0.12 | -0.51 | 200 | ≥7.5 |

| 40AH | 1.25-1.28 | 12.5-12.8 | ≥2786 | ≥35 | 302-326 | 38-41 | -0.12 | -0.51 | 220 | ≥7.5 |

| 38AH | 1.22-1.26 | 12.2-12.6 | ≥2786 | ≥35 | 287-310 | 36-39 | -0.12 | -0.51 | 220 | ≥7.5 |

| 35AH | 1.17-1.22 | 11.7-12.2 | ≥2786 | ≥35 | 263-287 | 33-36 | -0.12 | -0.51 | 220 | ≥7.5 |

| 33AH | 1.13-1.17 | 11.3-11.7 | ≥2786 | ≥35 | 247-271 | 31-34 | -0.12 | -0.51 | 220 | ≥7.5 |

| 30AH | 1.08-1.13 | 10.8-11.3 | ≥2786 | ≥35 | 223-255 | 28-32 | -0.12 | -0.51 | 220 | ≥7.5 |

| 28AH | 1.02-1.08 | 10.2-10.8 | ≥2786 | ≥35 | 199-231 | 25-29 | -0.12 | -0.51 | 220 | ≥7.5 |

![]()